When you're looking at flat roof replacement options, the choices really come down to four main players: TPO, EPDM, PVC, and Modified Bitumen. The right one for your property isn't a one-size-fits-all answer. It's about finding the sweet spot between your budget, how long you expect the roof to last, and how it will hold up to the intense South Florida climate.

Choosing Your Best Flat Roof Replacement Option

Picking a new flat roof is a major decision for any property owner. It directly affects your building's value, your monthly energy costs, and how well you're protected from the elements. Today's roofing materials are more advanced than ever, but you need to look past the sales pitch and see how they actually perform out in the real world.

To make an informed decision, ask yourself these practical questions: Does my roof need to withstand constant sun exposure like in Miami? Will it have heavy foot traffic from HVAC technicians? Answering these helps you avoid a cheap material that feels like a win upfront but ends up costing a fortune in repairs and higher cooling bills. We're here to give you a clear, honest breakdown to help you match the right material to your specific needs.

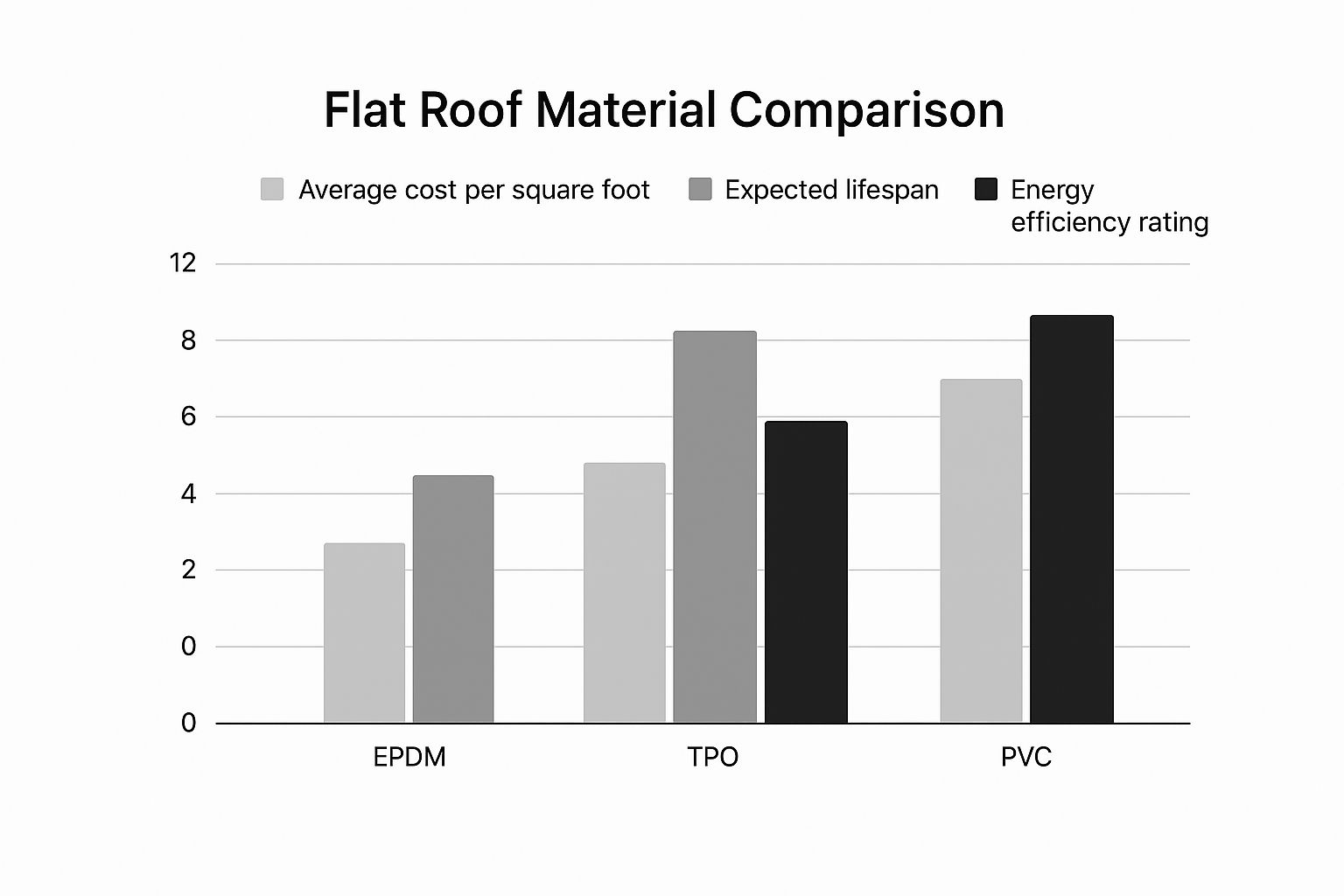

Key Material Differences at a Glance

Before we get into the nitty-gritty details, it helps to see how these options compare at a high level. This table gives you a quick snapshot of the landscape, covering the essential trade-offs between what you'll invest initially, how long you can expect it to last, and the standout feature of each system.

Quick Comparison of Flat Roofing Materials

| Material | Average Cost per Sq. Ft. | Estimated Lifespan | Key Advantage |

|---|---|---|---|

| TPO | $5 – $10 | 20-25 Years | Excellent energy efficiency and heat reflectivity. |

| EPDM | $4 – $9 | 25-30+ Years | Exceptional durability and UV resistance. |

| PVC | $6 – $12 | 25-30+ Years | Superior resistance to chemicals, fire, and punctures. |

| Modified Bitumen | $4 – $8 | 15-20 Years | Outstanding toughness and puncture resistance. |

This quick comparison should give you a solid starting point. As you can see, there’s a clear balance between upfront cost and long-term performance benefits.

What this chart really drives home is the trade-off. While materials like TPO and EPDM are easier on the initial budget, you can see how PVC's longer lifespan and top-tier energy efficiency make it a powerful contender for long-term value. Seeing the data visually like this helps put the decision you need to make for your property into perspective.

A Deep Dive into Single-Ply Membrane Roofing

When you look at modern flat roof replacement options, you'll see single-ply membranes have pretty much taken over the industry, and for good reason. These systems are made of a single, flexible layer of synthetic material rolled out right onto the roof deck. The result is a seamless, tough barrier against whatever the Florida skies throw at it.

Because they’re lightweight and go on fast, they’ve become the go-to for new buildings and re-roofing jobs alike.

This isn't just one product, though. It’s a family of materials, with the big three being TPO, EPDM, and PVC. Each one has its own set of strengths, and the best choice really comes down to your building's specific needs, our local climate challenges, and what you expect from your investment. Getting these differences is the key to making a smart decision that lasts.

The shift toward these systems is huge. The global market for flat roofing materials is currently valued at around $50 billion and is expected to climb to $80 billion by 2033. That growth is almost entirely thanks to property owners moving away from old-school, multi-layer roofs toward single-ply options that are simpler to install and perform better over the long haul. You can explore more data on these market trends to see just how dominant these materials have become.

TPO The Energy-Efficient Champion

Thermoplastic Polyolefin, or TPO, has quickly become a favorite, especially here in sunny South Florida. Its main claim to fame is its incredible energy efficiency.

TPO membranes are almost always a bright, reflective white. This creates a "cool roof" that bounces sunlight and heat away instead of soaking it up, which can take a massive load off your building's AC system. For a commercial property in Miami, this adds up to real, substantial energy savings over the roof's 20 to 25-year lifespan.

Its other big win is how the seams are sealed. We use a hot-air welder to join the TPO rolls, literally melting the edges together to form one continuous, solid membrane.

Actionable Insight: Request heat-welded seams for your TPO roof. This method creates a bond that's often stronger than the membrane itself, providing superior protection against leaks—the number one enemy of any flat roof. Unlike glued or taped seams, a proper weld fuses the material into a single, watertight sheet.

This makes TPO a fantastic choice for any building where keeping water out is the absolute top priority. While it’s tough, just know it’s not quite as resistant to chemicals or constant foot traffic as its cousin, PVC.

EPDM The Time-Tested Workhorse

Ethylene Propylene Diene Terpolymer, which everyone just calls EPDM, is basically a sheet of high-tech synthetic rubber. It’s been a reliable roofing workhorse for over 50 years, building a rock-solid reputation for durability and an impressive lifespan.

Unlike TPO and PVC, EPDM is a "thermoset" material, which means it's cured during manufacturing. This process gives it outstanding resistance to UV rays, ozone, and wild temperature swings. Its standard black color is a downside in hot climates, but it can actually help lower heating bills in colder states.

When looking at flat roof replacement options, EPDM stands out for a few reasons:

- Proven Lifespan: A properly installed EPDM roof can easily last 25 to 30 years, sometimes even longer. It’s a great long-term value.

- Flexibility: The rubber stays flexible in the cold, so you don't have to worry about it getting brittle and cracking.

- Puncture Resistance: Its rubbery nature makes it highly resistant to punctures from falling debris or hail.

The seams on an EPDM roof are sealed using special tapes and adhesives. While today’s adhesives are very good, these seams are still the system’s weakest point. For this reason, you should schedule bi-annual inspections specifically to check the seams and ensure they remain watertight.

PVC The Premium Protector

Polyvinyl Chloride, or PVC, is the premium player in the single-ply game, known for being exceptionally tough and resistant to just about everything. Just like TPO, it has heat-welded seams for a powerful, waterproof seal. But where PVC really shines is its ability to stand up to chemicals and fire.

This tough-as-nails profile makes PVC the only real choice for certain commercial buildings. Think restaurants with grease vents on the roof or industrial plants that emit chemical fumes—you need a material that won't break down from that kind of exposure.

Situational Recommendations for PVC:

- Restaurants and Food Processing: Specify PVC if your roof is exposed to animal fats or grease vents, as it won't degrade like other materials.

- Manufacturing Plants: Choose PVC to withstand exposure to a wide variety of industrial chemicals and pollutants.

- Airports and High-Traffic Areas: Select PVC for its top-tier puncture and fire resistance, making it a safer choice for busy buildings with strict fire codes.

PVC does have a higher upfront cost than TPO or EPDM. However, with a lifespan that can push 25 to 30+ years and its ability to handle the harshest environments, it often delivers a lower total cost of ownership when it’s the right fit for the job. Plus, its high reflectivity offers the same great energy savings as TPO, making it a powerful, all-around solution.

Evaluating Traditional Multi-Ply Roofing Systems

While the new single-ply membranes get a lot of attention, it would be a huge mistake to ignore the raw toughness of traditional multi-ply flat roof replacement options. Systems like Modified Bitumen and Built-Up Roofing (BUR) deliver a level of brute strength and built-in redundancy that many modern materials just can't replicate. For some South Florida properties, this old-school durability isn't just a nice-to-have; it's a must.

The strength comes from how they're built: multiple, overlapping layers of material that create a thick, formidable barrier against the elements. This multi-layer design is their superpower. If one layer gets damaged, there are others right below it to keep your building dry. This is a world away from single-ply systems, where one bad puncture can mean an immediate leak.

Modified Bitumen: The Flexible Powerhouse

Modified Bitumen, or "Mod-Bit" as we call it in the field, is the direct descendant of old-school asphalt roofing, but with some serious upgrades. Think of it as asphalt that's been reinforced with rubber or plastic polymers. The result is a material that’s both incredibly tough and surprisingly flexible.

We typically install Mod-Bit in two or three-ply systems, which gives it fantastic resistance to tears and punctures. This makes it a go-to choice for roofs that have a lot of foot traffic—think HVAC crews making regular service calls—or heavy equipment sitting on top. Those polymers also let the roof expand and contract with Florida's wild temperature swings without getting brittle and cracking, a huge improvement over older asphalt roofs.

Actionable Insight: If your flat roof sees a lot of foot traffic or has multiple AC units that need constant maintenance, choose a Mod-Bit system for its superior puncture resistance. It provides a much more durable surface than most single-ply membranes, which can drastically cut down on accidental damage and leaks.

Mod-Bit can be installed in a few different ways: torch-applied, cold-adhesive, or with self-adhering "peel and stick" rolls. A torch-down application creates an incredibly strong, seamless roof, but it’s a job for a highly skilled crew and involves open flames and serious safety protocols. For a safer, less disruptive installation with fewer fumes, ask your contractor about modern cold-applied or self-adhering options.

Built-Up Roofing: The Time-Tested Original

Built-Up Roofing (BUR) is the granddaddy of multi-ply systems, often known simply as "tar and gravel." For over 100 years, this has been the workhorse protecting commercial buildings. It’s constructed by layering bitumen (asphalt or coal tar) with reinforcing fabric felts, then topped with a layer of aggregate like gravel or crushed stone.

That top layer of gravel is BUR’s secret weapon. It does several critical things:

- Superior UV Protection: The gravel acts as a natural sunblock, shielding the asphalt layers from South Florida's brutal sun and preventing them from breaking down.

- Excellent Fire Resistance: The stone surface gives the roof a high level of protection from external fire threats.

- Impact Resistance: It can take a beating from hail or falling debris far better than an unprotected membrane ever could.

The sheer mass and multiple layers of a BUR system make it almost bulletproof. But all that toughness comes with a lot of weight. Before you can even consider a BUR system, you must hire a structural engineer to confirm your building can handle the load. This step is non-negotiable and can be a deal-breaker for many properties.

Practical Trade-Offs You Must Consider

When you choose a multi-ply system, you’re making a conscious trade-off. You're getting unmatched durability, but the installation is more labor-intensive, messier, and potentially riskier than with single-ply options.

Key Decision Factors for Multi-Ply Systems:

| Consideration | Modified Bitumen | Built-Up Roofing (BUR) |

|---|---|---|

| Puncture Resistance | Excellent. The multi-layer design and polymer reinforcement make it very tough. | Outstanding. The gravel top layer provides maximum protection against impact. |

| Structural Weight | Heavier than single-ply but manageable for most buildings. | Extremely heavy. A structural assessment is mandatory. |

| Installation | Complex. Torch-down methods carry a fire risk and require specialized skill. | Very labor-intensive. Messy, with strong fumes from hot tar. |

| Best Use Case | Roofs with high foot traffic that need both toughness and flexibility. | Buildings that need the absolute best UV and impact protection and can support the weight. |

At the end of the day, these classic flat roof replacement options offer a different kind of value. They trade the sleek, energy-efficient profile of single-ply systems for raw toughness and a track record that's been proven over decades. For property owners who put durability above all else, multi-ply systems are still a powerful and very relevant choice.

Analyzing the Total Cost of Your Roof Replacement

When you're looking at quotes for a flat roof replacement, it's easy to get fixated on the initial price tag. But that number is just the beginning of the story. A truly sound investment means looking beyond the installation cost and understanding the total cost of ownership. This is the real-world cost of your roof over its entire life, factoring in maintenance, repairs, and especially here in Florida, energy savings.

The final bill isn't just about the material you pick. Far from it. The complexity of your roof, whether we need to do a full tear-off of the old system, any insulation upgrades, and local labor rates all have a major impact. A simple, small roof is a completely different job than a sprawling commercial surface dotted with pipes, vents, and HVAC units.

Breaking Down the Cost Drivers

Any roofer worth their salt will give you a transparent quote that breaks down exactly what you're paying for—not just a single number at the bottom.

- Material Costs: This is the most obvious one. Prices can vary quite a bit between EPDM, TPO, PVC, and Modified Bitumen.

- Labor and Installation: This is a big piece of the puzzle, often making up 40-60% of the total project cost. A more hands-on installation, like a torch-down Mod-Bit system, naturally requires more skilled labor and time.

- Tear-Off and Disposal: If we have to remove the old roofing layers, that's a labor-intensive job with its own disposal fees. A "roof-over" might seem cheaper upfront, but it can hide serious problems with the underlying roof deck.

- Insulation: We almost always recommend upgrading your insulation, especially in our climate. It adds to the initial cost, sure, but it pays you back year after year in lower energy bills.

- Permits and Inspections: These are non-negotiable administrative costs that ensure your new roof is fully compliant with South Florida building codes.

Thinking this way is crucial. The cheapest roof to install can easily become the most expensive one over two decades if it demands constant, costly maintenance. This long-term financial view is becoming the standard. The flat roofing market, valued at around USD 10.5 billion in 2023, is expected to climb to USD 16.8 billion by 2032. This growth is all about homeowners and property managers demanding systems that deliver lasting value and efficiency. You can read more about these global roofing market trends to see how the industry is shifting toward smarter, more sustainable investments.

The Long-Term Financial Picture

Let's put this into practice. We’ll compare the total cost of ownership over 20 years for a standard 2,000-square-foot roof. This table really highlights how an initially cheaper option can end up costing you more once you account for upkeep and energy performance.

Total Cost of Ownership Comparison

This analysis projects the initial installation costs, estimated maintenance, and potential energy savings over a 20-year period for different flat roofing materials. It gives you a much clearer picture of the true long-term investment.

| Material Type | Initial Cost (per 2000 sq. ft.) | 20-Year Maintenance (Est.) | 20-Year Energy Savings (Est.) | Total 20-Year Cost |

|---|---|---|---|---|

| EPDM (Black) | $12,000 | $3,500 | $1,000 | $14,500 |

| Modified Bitumen | $11,000 | $5,000 | $1,500 | $14,500 |

| TPO (White) | $14,000 | $2,000 | $5,000 | $11,000 |

| PVC (White) | $18,000 | $1,500 | $5,500 | $14,000 |

Note: These are estimates for illustrative purposes. Actual costs will vary based on your location, contractor, and specific project details.

The numbers don't lie. While Modified Bitumen looks like the bargain upfront, its higher maintenance needs and poor energy performance bring its 20-year cost right up to match EPDM. The real winner here is TPO. Even with a higher installation price, its minimal maintenance and fantastic energy savings make it the most cost-effective choice by a long shot over two decades.

Actionable Insight: In a climate like South Florida, the ROI from an energy-efficient "cool roof" like TPO or PVC is massive. Ask your contractor to calculate your potential energy savings. The money you save on air conditioning isn't just a small bonus; it's a major financial win that can completely offset the higher installation price in as little as 5-7 years.

At the end of the day, evaluating your flat roof replacement options through the lens of total cost of ownership is how you protect your investment. It shifts your focus from just finding the cheapest price today to securing the best possible value for your property tomorrow.

Matching Your Roof to Your Climate

Picking the right material from a list of flat roof replacement options without thinking about our local South Florida weather is a huge mistake. It’s like buying a convertible for a place that rains 300 days a year. A roof’s real-world performance is completely tied to its environment, and down here, that environment is demanding.

Your roof isn't just a lid for your building; it’s a shield. It has to stand up to brutal UV rays, suffocating humidity, and the ever-present threat of hurricane winds. If you ignore these factors, you’re just setting yourself up for leaks, premature failure, and expensive headaches. Get it right, though, and you’ve got a tough, long-lasting investment that actually puts money back in your pocket.

Battling the Sun with Cool Roof Technology

Here in South Florida, the sun is more than just bright—it's a relentless force that can bake your building and make your cooling costs explode. A standard dark-colored roof easily soaks up enough solar heat to reach temperatures over 150°F. All that heat goes straight into your property, forcing your AC to work nonstop just to keep up.

This is exactly where "cool roofs" come in. They aren't a gimmick; they are a practical, money-saving solution that uses highly reflective materials to send sunlight back where it came from.

- White TPO and PVC Membranes: These are the undisputed champions of cool roofing. Their brilliant white surfaces can reflect as much as 80% of the sun's rays. This keeps the roof itself, and everything underneath it, drastically cooler.

- Direct Cost Savings: A cooler roof means less work for your air conditioner. For a commercial building in Miami, that can translate to a 10-30% drop in peak cooling demand. Over the life of the roof, that’s a massive financial win.

Your action step is clear: for any South Florida property, make a white TPO or PVC system your default choice. This proactive strategy starts cutting your operational costs from the very first day and provides the best long-term value in our climate.

Defending Against Wind and Water

Anyone who’s lived through a hurricane season here knows that wind uplift and driving rain are a roof's worst enemies. During a big storm, the wind screaming over your roof creates powerful suction that tries to rip it right off. The seams are always the weakest link in this fight.

This is why the seam strength and the installation method aren't just details—they're what will determine if your roof survives the storm.

Actionable Insight: For maximum hurricane resistance, specify a fully adhered single-ply membrane in your contract. With this method, the entire membrane is bonded directly to the insulation board using a powerful adhesive. This creates a single, solid surface with no loose edges for the wind to catch, giving you a serious advantage against catastrophic wind damage.

Mechanically fastened systems, which use screws and plates, are common and can be effective. But the seamless bond of a fully adhered system gives you superior protection. Combine this with the heat-welded seams of TPO and PVC, and you get a waterproof bond that is often stronger than the membrane itself, providing the ultimate defense when the weather gets ugly.

Making the Final Choice and Hiring a Pro

You've done the homework. You understand the materials, the costs, and what South Florida’s climate demands from a roof. Now comes the most important part: making the final call and finding the right pro to install it. Honestly, picking the contractor is just as critical as picking the material itself.

Your final decision really boils down to your own specific needs. Are you playing the long game and want the lowest lifetime cost that TPO can offer? Or maybe you have a roof deck with high foot traffic and need the sheer toughness of Modified Bitumen. The "best" choice is simply the one that fits your property's daily use, your budget, and what you expect from your roof down the road.

Vetting Your Roofing Contractor

Finding a reputable, skilled roofing contractor in South Florida is the absolute key to a successful project. You can choose the best material in the world, but if it’s installed poorly, you’ll never get the performance and lifespan you paid for. Rushing this step is a surefire way to cause future headaches and expensive repairs.

Before you sign any contracts, you must properly vet any potential contractor. You want a team that’s honest, communicates clearly, and has the local projects to back up their claims.

The demand for skilled roofers is no secret. The global flat roofing market is already valued at roughly $58.1 billion as of 2025 and is expected to grow at 7.1% annually through 2033. This boom underscores how vital it is to partner with an established, professional company that knows how to get the job done right.

Your Final Checklist for Hiring a Pro

To make sure your investment is protected, you need to be methodical when evaluating contractors. Don't just jump at the lowest price—a suspiciously cheap quote is often a sign that they're cutting corners on materials or labor.

Actionable Insight: Always insist on getting at least three detailed, itemized quotes. A true professional will provide a breakdown of costs for materials, labor, removing the old roof, disposal, and permits. This transparency prevents surprise charges later. If a contractor just gives you one vague number, that's a huge red flag.

Use this checklist to make sure you're hiring a real professional:

- Verify Licensing and Insurance: Ask to see their Florida state license, proof of liability insurance, and workers' compensation coverage. This is non-negotiable and protects you from being held liable for any accidents on your property.

- Check References and Past Projects: A good roofer will be proud of their work. Call their references. Better yet, drive by a few of their recent local jobs to see the quality for yourself.

- Review the Warranty: A reputable company stands behind their work. They should offer a solid warranty covering both the materials and their installation quality. Make sure you understand the terms and duration.

- Analyze the Quote Thoroughly: The contract should be crystal clear. It needs to specify the exact materials being used, a detailed scope of work, and a realistic timeline for when the project will be finished.

By being diligent in choosing both your material and your roofer, you can be confident that your new flat roof will be a durable, long-lasting asset for your property.

Answering Your Top Questions About Flat Roofs

Choosing the right flat roof replacement option is a big decision, and it’s natural to have questions. We hear a lot of the same concerns from property owners, so we've put together some straightforward answers to help you feel confident about this important investment.

How Long Should a New Flat Roof Last?

The lifespan of your new flat roof really boils down to two things: the material you choose and the quality of the installation. For today's popular single-ply systems, here’s what you can generally expect:

- EPDM and PVC: These are the premium choices for a reason. With proper care, they often last 25-30 years, and sometimes even longer.

- TPO: This is a fantastic, energy-efficient option that typically gives you a solid 20-25 years of performance.

To ensure your roof reaches its maximum lifespan, schedule bi-annual professional inspections. This proactive care allows you to catch and fix small issues before they turn into major, expensive headaches.

Can I Install a New Roof Over My Existing One?

Sometimes, yes. This is called a "roof-over" or recovery, but it’s rarely the best move and comes with strict rules. Building codes usually only allow it if you have just one existing roof layer and the structure underneath is in perfect shape.

Your best action is to insist on a full tear-off. It’s the only way for a contractor to inspect the roof deck for rot or other hidden damage. This step guarantees your new membrane is laid on a solid foundation, which is essential for long-term performance and validating your warranty.

What Is a Cool Roof and Do I Need One in South Florida?

A "cool roof" is simply a roofing system designed to reflect more sunlight and absorb less heat. It's a simple idea with a powerful impact, keeping the inside of your building cooler and taking a significant bite out of your air conditioning bills.

For any property owner in South Florida, the answer is an emphatic yes. The intense, year-round sun means that materials like white TPO and PVC can deliver substantial energy savings. Don't consider it an optional feature; treat it as a financial strategy. The savings on your cooling costs will pay for the roof over time.

Ready to talk about the best flat roof replacement options for your building? The team at Exact Roofing is here to give you expert advice and professional installation, ensuring your investment is protected for decades. Get your free estimate from Exact Roofing today.